labizoni

New member

Hi folks!

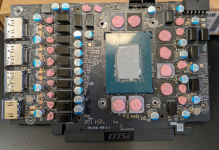

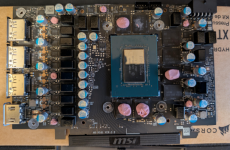

So I've installed the 10248 block in a 5080 Shadow, which shares the same pcb with of Ventus cards and also, the Shadow is listed as compatible w/ the 10248.

However, there's a issue. The pcb warps once the block is installed.

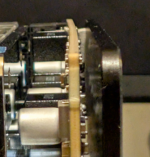

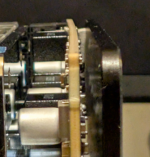

If the nut standoff makes contact with the pcb, as per picture below...

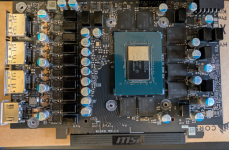

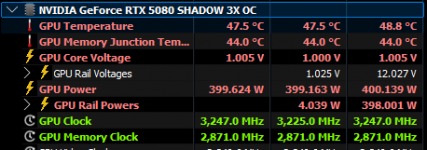

The pbc warps a lot like the picture below.. Lucky it did not damage the card, but once the pc loaded into windows I got artifacts straight away..

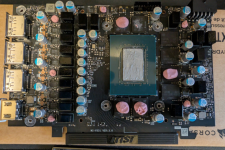

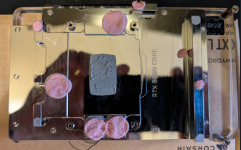

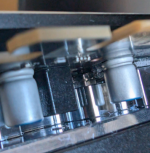

If the screws are not tightened as they should be (because I believe this space in between the pcb and the nut standoff is not by design), the card warps way less..

The thermal pads are (were) the ones supplied. Once I noticed the artifacts, I OFC disassembled the whole thing wasting PTM and put together again. The pcb was still warping. Took apart again, and used putty (thinking it might be a thermal pad thickness issue), which also warped. Took apart again wasting more PTM (for the fourth time) and used very soft liard tflex hd90000 1mm and did not tight the screws well and the result is like the pictures above, a good gap in between the pcb and the standoffs and just slightly warped. - but no artifacts. I'd like to stress the fact this whole thing could have damaged the card.

So, what to do?

So I've installed the 10248 block in a 5080 Shadow, which shares the same pcb with of Ventus cards and also, the Shadow is listed as compatible w/ the 10248.

However, there's a issue. The pcb warps once the block is installed.

If the nut standoff makes contact with the pcb, as per picture below...

The pbc warps a lot like the picture below.. Lucky it did not damage the card, but once the pc loaded into windows I got artifacts straight away..

If the screws are not tightened as they should be (because I believe this space in between the pcb and the nut standoff is not by design), the card warps way less..

The thermal pads are (were) the ones supplied. Once I noticed the artifacts, I OFC disassembled the whole thing wasting PTM and put together again. The pcb was still warping. Took apart again, and used putty (thinking it might be a thermal pad thickness issue), which also warped. Took apart again wasting more PTM (for the fourth time) and used very soft liard tflex hd90000 1mm and did not tight the screws well and the result is like the pictures above, a good gap in between the pcb and the standoffs and just slightly warped. - but no artifacts. I'd like to stress the fact this whole thing could have damaged the card.

So, what to do?

Last edited: