You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

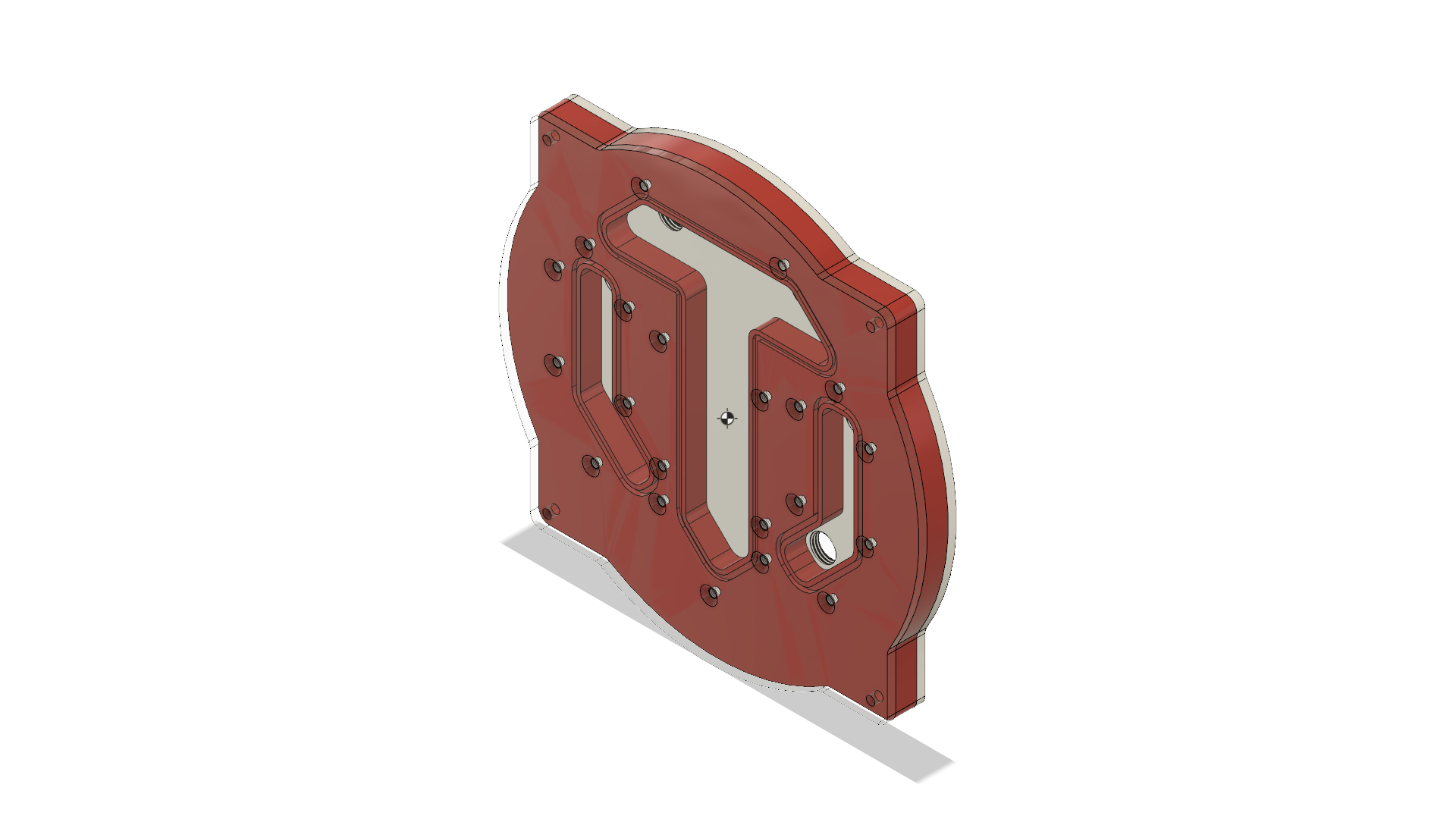

Distro plate feedback

- Thread starter Creative

- Start date

And this part is for?

As far i know the distro plates are used like reservoir from a lot of modders and there is only one company who sales this product to end user.

So your intension is the same to use it as reservoir right?

So your intension is the same to use it as reservoir right?

Creative

Member

I intended it to be used as a distibution point, for a reservoir they are way to small.

One side is feed by the pump, from that side both the inlet of the cpu and Gpu waterblock can be feed.

The outlets of the gpu and cpu are plumed in the other side of the distro plate. the retun side of the plate needs to be conected too the radiatours and the pump too finish off the loop.

One side is feed by the pump, from that side both the inlet of the cpu and Gpu waterblock can be feed.

The outlets of the gpu and cpu are plumed in the other side of the distro plate. the retun side of the plate needs to be conected too the radiatours and the pump too finish off the loop.

davido_labido

Moderator

Hi Creative - Dave here, I started life in the industry as a modder and PC builder sponsored by many companies (including Alphacool!)

Distro plates are a great idea for reducing the need for complicated tube runs and/or to get that visual look you want to create. Your idea will work as long as you're using a pump that can handle it, it will increase restriction though (as with every component) but how much will only be seen when you try it.

It should look interesting for sure!

Also, if you add a fill port to it, you could use it as a reservoir at a 120mm size (even an 80mm!) however, you would have to add a separate reservoir to feed the distro plate whilst you filled the loop, then remove it once there was enough fluid to fill the loop again. This is how I have done it a couple of times (and also done reservoir free loops!) they work well, but are a lot trickier to fill and empty

Distro plates are a great idea for reducing the need for complicated tube runs and/or to get that visual look you want to create. Your idea will work as long as you're using a pump that can handle it, it will increase restriction though (as with every component) but how much will only be seen when you try it.

It should look interesting for sure!

Also, if you add a fill port to it, you could use it as a reservoir at a 120mm size (even an 80mm!) however, you would have to add a separate reservoir to feed the distro plate whilst you filled the loop, then remove it once there was enough fluid to fill the loop again. This is how I have done it a couple of times (and also done reservoir free loops!) they work well, but are a lot trickier to fill and empty

Creative

Member

but i digress. my maine question is if alphacool would be interested in addding distro plates to there sortiment.

i have a couple idears for other size plates and reservoirs that need a it of polish.

If you/alphacool are interested i can share them here or give you the rugh 3d file to work of...

i have a couple idears for other size plates and reservoirs that need a it of polish.

If you/alphacool are interested i can share them here or give you the rugh 3d file to work of...

Wow that looks really nice

i dont quite understand how you want to do two sepered loops with it.

it only has 3 flow chanbers

i think it needs 4 to work with a dual loop systehm

No, it needs two chambers as a matter of fact. But since the World of Tanks logo has three parts (the T in the middle and the curve chambers at the sides), the reservoir (because that is what it is in the end) will have the curved chambers connected via a tube at the back. There are 6 G1/4 holes in total, two for each chamber. As for the curved chambers, the liquid enters one, exits it and enters back in the other, then goes to the loop.

The T chamber will be filled with white liquid and the side chambers will be filled with red liquid.

4mm each, the middle one has 10mm thickness. I chose 4mm for the external plates simply because I happened to already own them physically. I went for a sandwich method because the front face is supposed to have no holes except for the screw ones.whats the thicknes of the two pices yof acrylic for the top and botom of the reservoir ?