Interesting idea, but I'm sorry to counter this idea.

Let me explain why.

Imprint 1mm dark grey pads original aircooler

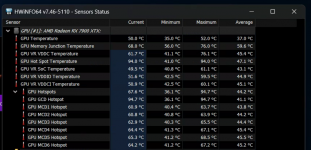

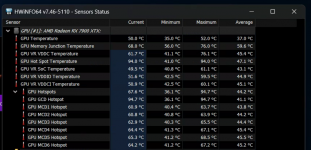

Let's take a look to the 1mm thermal pads on the original XFX heatsink first.

In my opinion this imprint on the 1mm pads look exeptionally good. (dark grey ones)

View attachment 5247

Imprint 1mm dark grey pads Alphacool waterblock

Hang on there, i'm giving my thoughts below

I'm seeing less pressure here on the pads. Nothing to panic about ofcourse. Just sharing info.

Though I notice less pressure on the thermalpaste in the middle. Where the GCD is located in the die.

View attachment 5248

Could these be the problem?

I'm only marking two of them to prevent clutter. Nothing wrong with these two in particular, but hese offsets, standoffs, spacers, washers. However you want to call them. They might be marginally too high or maybe uneven. Even though this seems impossible since Alphacool probably uses top tier 3d scanners and ports the model over to their CNC machine. Try screwing them tight.

What I'm basically saying is that changing your pads to thinner ones will

worsen your performance. Because these washers limit your PCB.

View attachment 5246

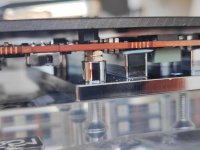

Closer view

View attachment 5245

What's up next?

This depends on Alphacool's feedback. It's unfortunate, but for the time being I'm not going to modify this block. Would kill the 2y waranty.

Changing the washers after measuring with a lasermeter would be an option.

Modifying the PCB to release tension on the center so the bulge can disappear would be an option.

Ordered a Thermal Grizzly

Kryosheet for testing purposes.

I highly recommend trying out

AMD Chill to prevent unnecessary heat dispersion in games where you don't benefit the extra power until there's a proper solution to our junction temperature.

We'll see.

Enjoy the weekend all.