You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

XFX 7900XT merc 310 high junction temperature

- Thread starter DirtyAlpaca

- Start date

I had a similar problem on an Asrock RX 7900 XTX Phantom Gaming. I first used ARCTIC MX-6 thinking it would be better than whatever was in the box. I was getting around 65 deg edge temperature but up to 105 deg junction temperature. I did try loosening the screws (but not fully removing the cooler) but nothing changed. After opening it up, I saw that one part of the die (upper middle of the die if the PCI-E connecter is the bottom) had almost no paste but the rest of the die still had a thick layer of paste. If anyone wants to see photos, I can upload them.

I've now removed the cooler and installed a (probably legitimate) PTM7950 and when reinstalling, installed the cooler screws with only two fingers and relatively low force. Now, I am getting about 50 deg edge temperature and 80 deg junction temperature (and some say it will get even better with some usage cycles). The delta is still higher than I would expect but atleast there is now headroom before the 110 deg limit.

I've now removed the cooler and installed a (probably legitimate) PTM7950 and when reinstalling, installed the cooler screws with only two fingers and relatively low force. Now, I am getting about 50 deg edge temperature and 80 deg junction temperature (and some say it will get even better with some usage cycles). The delta is still higher than I would expect but atleast there is now headroom before the 110 deg limit.

blackwell1988

New member

Ok, sounds like the same mistake as most people here. Apparently, this chiplet design causes the problem that with "normal" thermal pastes (NH-2, MX4, etc.) a "pump out" effect is created, i.e. the paste may become too liquid and run off between the chips.

While this may be part of the issue, that fact that only the upper middle (more like top middle) lacked paste as opposed to all of the die or even just the middle of the die suggests that there was an uneven contact problem too.Ok, sounds like the same mistake as most people here. Apparently, this chiplet design causes the problem that with "normal" thermal pastes (NH-2, MX4, etc.) a "pump out" effect is created, i.e. the paste may become too liquid and run off between the chips.

Last edited:

Registered just to mention it seems I have the same issue with the Nitro+ version of the waterblock. I've used the same loop for a 2080ti and 6900xt and thought I needed to upgrade the pump and radiator (previously 1x 280 radiator, now 2x 280 ones) but the result is pretty much the same: junction temperature over 100C, hitting 110C on cyberpunk's benchmark, but with older games it stays under 60C (probably wouldn't even notice there was a problem if I didn't install cyberpunk just to see how the RT support is doing on linux). Bought a torque screwdriver and both the Kryosheet (have clapton tape) and PTM (in case I don't manage to get the Kryosheet in place) to give it a try and will report the results.

Kryosheet solved it. Maximum temperature I could get while using cyberpunk and RDR was 76C. Put clapton tape all around the die and used drops of thermal paste on the corners to help keep the kryosheet in place. Just a note for other ogres like me planning to do this: careful that this sheet tears very easily. Thanks @DirtyAlpaca and others in this thread!Registered just to mention it seems I have the same issue with the Nitro+ version of the waterblock. I've used the same loop for a 2080ti and 6900xt and thought I needed to upgrade the pump and radiator (previously 1x 280 radiator, now 2x 280 ones) but the result is pretty much the same: junction temperature over 100C, hitting 110C on cyberpunk's benchmark, but with older games it stays under 60C (probably wouldn't even notice there was a problem if I didn't install cyberpunk just to see how the RT support is doing on linux). Bought a torque screwdriver and both the Kryosheet (have clapton tape) and PTM (in case I don't manage to get the Kryosheet in place) to give it a try and will report the results.

Snuggis

New member

So I have the same problem with my Merc 310 with an Eisblock. GCD at ~90°C, the MCDs at high 40s-mid 50s °C during short stress test (in the AMD software). The thermalpaste that came with the block, believe it was Subzero, was very tough to spread, so I tried repasting with some Noctua NT-H1 instead. Gave slightly better results but I'm not really satisfied. The thermal pads feel very brittle, so I'll feel like I need to get some replacements for those when I get around to taking it apart again.

Now I tried looking into this around the web and I still feel like I'm not that much wiser. I do have an unopened package of Conductonaut laying around, but I couldn't really found much info about liquid metal on these chips. Should I give it a go, or is it very sketchy with the chiplet design? And if it is, should I get the Kryosheet or PTM7950? I feel like the Kryosheet quickly becomes very expensive unless there's something else I need that I could get from the same place. The Kryosheet itself is not too bad, even though it is on the more expensive side. Last I checked it totalled around €30-35 with shipping and taxes. The cost of PTM7950 isn't something to think about, but it could take quite a while for it to arrive.

Now I tried looking into this around the web and I still feel like I'm not that much wiser. I do have an unopened package of Conductonaut laying around, but I couldn't really found much info about liquid metal on these chips. Should I give it a go, or is it very sketchy with the chiplet design? And if it is, should I get the Kryosheet or PTM7950? I feel like the Kryosheet quickly becomes very expensive unless there's something else I need that I could get from the same place. The Kryosheet itself is not too bad, even though it is on the more expensive side. Last I checked it totalled around €30-35 with shipping and taxes. The cost of PTM7950 isn't something to think about, but it could take quite a while for it to arrive.

I'd say it depends on what you want.

PTM7950 is relatively inexpensive + uncomplicated to apply + those who used it (including myself) had solid results. I recommend it in order to rule out issues with thermal paste.

I guess you can have even more effective cooling with electrically conductive graphene pads or liquid metal but applying those (flawlessly) depends on your skill set and experience - we cannot asses that. You should only use it if you want to really optimize your cooling and you already have experience applying it (or you're willing to take on the risk).

PTM7950 is relatively inexpensive + uncomplicated to apply + those who used it (including myself) had solid results. I recommend it in order to rule out issues with thermal paste.

I guess you can have even more effective cooling with electrically conductive graphene pads or liquid metal but applying those (flawlessly) depends on your skill set and experience - we cannot asses that. You should only use it if you want to really optimize your cooling and you already have experience applying it (or you're willing to take on the risk).

Snuggis

New member

I've used liquid metal a few times before with good results. 7700K and 8700K delid and my 6900 XT has been running with liquid metal for the past two years.

Guess I'll try it when I have some thermal pads on hand in case they don't agree with the block being unmounted a third time.

Guess I'll try it when I have some thermal pads on hand in case they don't agree with the block being unmounted a third time.

blackwell1988

New member

I can also broadly agree with dcox12's statement.

If you have experience with liquid metal, there is nothing to say against it. When it comes to the chiplet design and usage, I haven't come across much on the internet.

I use the cryosheet on my Merc310. Yes, it is more expensive, but it will never dry out, i.e. “maintenance-free”.

As I described above, not easy to place, but great results and no more problems.

I replaced the thermal pads straight away.

If you have experience with liquid metal, there is nothing to say against it. When it comes to the chiplet design and usage, I haven't come across much on the internet.

I use the cryosheet on my Merc310. Yes, it is more expensive, but it will never dry out, i.e. “maintenance-free”.

As I described above, not easy to place, but great results and no more problems.

I replaced the thermal pads straight away.

Snuggis

New member

Thanks for the input! Which thermal pads did you use?I can also broadly agree with dcox12's statement.

If you have experience with liquid metal, there is nothing to say against it. When it comes to the chiplet design and usage, I haven't come across much on the internet.

I use the cryosheet on my Merc310. Yes, it is more expensive, but it will never dry out, i.e. “maintenance-free”.

As I described above, not easy to place, but great results and no more problems.

I replaced the thermal pads straight away.

blackwell1988

New member

I use Thermal Grizzly's MinusPads to strengthen the AlphaCool in the instructions.

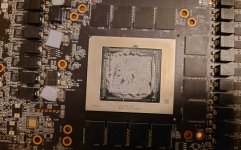

I also tried the Honeywell PTM 7950. After the installation just before christmas it seemed ok: around 85°C in Timespy Extreme and around 95°C in Cyberpunk. But it got worse over time, in Alan Wake 2 i noticed 110°C on the Hotspot with just 300W Power Draw (7900XTX with Stock PL of 400W) today. What could this be? The Imprints on the Chip and GPU block seem ok to me.

Last edited:

Hard to tell because of the reflections of the flash and the focus being slightly off. From what I see nothig is obviously wrong.

You can only try again and thighten the screws differently (others here had some success with that). We do know that using PTM can mitigate the issue that many here experienced using thermal paste.

But in the end Alphacool's cooling blocks for the Merc310 do have tolerance issues - I think that's a fair conclusion at this point and thus there's just no golden rule how to deal with that.

Also keep in mind that temperature issues can emerge from other parts of the loop, too. I personally like to keep an eye on CPU and water temperature. If those also are higher than normal/expected, the GPU cooler shouldn't be the problem.

You can only try again and thighten the screws differently (others here had some success with that). We do know that using PTM can mitigate the issue that many here experienced using thermal paste.

But in the end Alphacool's cooling blocks for the Merc310 do have tolerance issues - I think that's a fair conclusion at this point and thus there's just no golden rule how to deal with that.

Also keep in mind that temperature issues can emerge from other parts of the loop, too. I personally like to keep an eye on CPU and water temperature. If those also are higher than normal/expected, the GPU cooler shouldn't be the problem.

bassochist

New member

same issues with my alphacool block for the saphire 7900xtx, had to repaste it 3 times now, but the block keeps pushing all the thermal paste to the sides, so much that there isn't anything left on the gpu die, i replaced every thermal pad (the ones included are really low quality) now and repasted with mx6, and it seems to do a lot better now.

I'm honestly tired of dis- and reassembling the waterblock. I've tried the included Alphacool Subzero, then tried some MX-4 i had lying around (twice) then i bought more Alphacool Subzero and just recently i applied PTM 7950, also twice.

I've now tried to make sure the PCB is even, I Screwed the 4 screws around the GPU-Chip handtight and then one turn outward to have even pressure around the die.

It's now at 95°C Hotspot in Cyberpunk at 100% Powerlimit with unlocked FPS and an Undervolt to 1100mV.

My CPU shouldn't put too much stress in the loop (5800X3D).

With my previous 2080 Ti on a Phanteks Block i had higher Water Temps despite a lower Power Limit, which suggests it transfered more heat into the coolant. Also i assembled this block exactly once and it worked perfectly, it even was the first waterblock i ever installed on a GPU.

I've now tried to make sure the PCB is even, I Screwed the 4 screws around the GPU-Chip handtight and then one turn outward to have even pressure around the die.

It's now at 95°C Hotspot in Cyberpunk at 100% Powerlimit with unlocked FPS and an Undervolt to 1100mV.

My CPU shouldn't put too much stress in the loop (5800X3D).

With my previous 2080 Ti on a Phanteks Block i had higher Water Temps despite a lower Power Limit, which suggests it transfered more heat into the coolant. Also i assembled this block exactly once and it worked perfectly, it even was the first waterblock i ever installed on a GPU.

And this could be the point where things went wrong.I've now tried to make sure the PCB is even, I Screwed the 4 screws around the GPU-Chip handtight and then one turn outward to have even pressure around the die.

I applied the PTM and then I thightened the screws firmly. Not with force but they are really tight. This of course caused the PCB to bend but I don't care much because I use PTM.

I still stick with my (unproven) theory that the bent PCB results in tiny contact problems which cause issues if you use thermal paste. But using thermal pads like PTM or thermal grizzly (or liquid metal which has a "unique" viscosity) you can defeat those tiny contact problems caused by the bent PCB. But I don't have the means to peroperly investigate and verify or falsify my theory.

Long story short: If using PTM, screw it thight. That worked very well for me.

Okay, i think i'll give that a try, although i tried to change the pressure of the 4 screws around the PCB while it was running (which i know you schouldn't do) and decreasing the pressure on these screws lowered the hotspot temperature. Also the backplate contributes quite a bit to the temperatures as well, without it was at 105°C and with backplate at 95°C.Long story short: If using PTM, screw it thight. That worked very well for me.