Received my blocks at the start of August and thought I'd provide some feedback.

Have 2x Gainward 3080 Phantoms - ordered 2x blocks and the Acool Aurora GPX SLI connector.

Firstly some feedback regarding the SLI connector - the water jackets on the blocks and SLI connector are oval shaped - the O-rings are O shaped. I found the recess on the SLI connector ( my one at least ) was not deep enough so had an extremely difficult time having the O rings seat correctly on the connector when mounting onto the block.

Very frustrating and difficult to mount as the O-rings kept popping out when trying to connect the cards together.

After trying numerous times filling up my loop and getting leaks at the O-rings / connectors - I decided to scrape away some of the acrylic to make the recess deeper so the Orings would stay in place long enough so I could get a water tight seal.

I may have received a bad SLI connector but I think this may be a design fault as the recesses in the original blocks ( which are also oval shaped ) the O-Rings fit without popping out.

Eventually worked - but as a customer I shouldn't have to resort to doing this

@Thomas_S / Acool please review these blocks to ensure the O-rings seat properly and the recesses are within tolerance in SLI GPX connectors!

Either that or provide some oval shaped gaskets / O-Rings which will fit correctly and stay in place for installation

Now onto the blocks - used all the pads included and followed instructions. After I fixed the SLI connector issue booted it up and was getting roughly 76c whilst mining - a reduction from 95c with the air cooler.

After a couple of weeks I found one of my cards started to hit 90c while mining ( first card in the loop / the other card stayed around 76 )

From this forum - realised some pads may not be getting good contact with cold plate so decided to drain the rig and open the cards up again. Before doing that I ordered some Thermalright 12.8 w/mK pads - 1mm and 1.5mm.

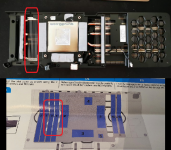

When I opened the hotter card - found that the some pads covering LR22 chips was not making good contact.

Memory chips seemed to be ok but some could have been better - found an oily residue left on the mem chips from the Acool thermal pads provided

Replaced memory chips with Thermalright 1mm pads - replaced the other strips with 1.5mm as the forum suggested.

Did this with both cards.

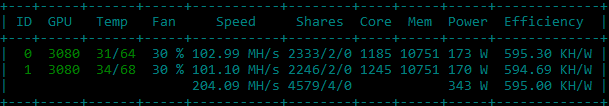

With the Thermalright pads in - the hotter card has now reduced mem temps to 60c while mining - yes 30c less than stock pads.

The other card is roughly 4c higher - this can be expected as the the hot coolant from card 1 goes straight to card 2 before going into a radiator

Hope this helps someone!

Edit - Sorry guys didn't take photos as I really wasn't in the mood to take my time messing around with it. Wife was already upset that I had computer parts everywhere.

Edit 2 - uploaded mining mem temps. Ambient temps have picked up in Australia and no air conditioning in my room but at 5am before work temps were 60/64